Not Finding What You're Looking For?

Contact UsCustom Piston Ring Manufacturing Capabilities

Custom engineered and manufactured piston rings, and seal rings are essential to the successful functionality of any application. They are specifically designed to form a seal between the piston and the cylinder wall. Once the seal is formed, pressurized gases are prevented from escaping.

Precision rings, incorporated understands custom quality manufacturing. They have been designing and manufacturing custom piston rings for over 70 years and providing the highest quality standards for all their project designs. Whether it’s custom design manufacturing, heat treatment, turning, grinding, or milling, Precision rings, incorporated’s experts provide what is needed.

Learn more about Precision rings, incorporated’s piston ring and seal ring custom design and manufacturing capabilities by contacting the sales team or calling 317-247-4786 for assistance.

Piston Ring and Seal Ring Custom Capabilities

Precision rings, incorporated (Pri) is a leading manufacturer and supplier of piston rings, focusing on custom design and fabrication.

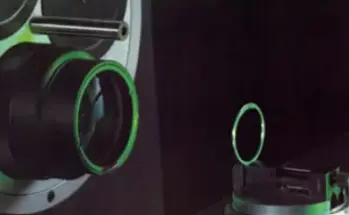

Piston Rings

Precision rings, incorporated specializes in piston rings for harsh environments, including extreme temperatures, high pressures, and tight tolerance requirements. The engineering team can manufacture piston rings from custom prints and provide custom piston ring engineering services designed to the application requirements.

Seal Rings

Custom manufactured seal rings provide enhanced sealing capabilities for a broad range of applications. Seal rings are typically used in applications where leakage is critical. Types of seal rings include but are not limited to two-piece and three-piece ring assemblies.

Contracting and Expanding Rings for Power Generation

Precision rings, incorporated has been designing and manufacturing expanding rings and contracting rings used in power generation for decades. Piston rings produced are used in the nozzles of large turbines, sealing different sections or stages, and in gearboxes. Precision rings, incorporated also manufactures shaft seals for sealing a spinning shaft against a stationary housing. Commonly referred to as contracting rings, these rings seal on the inside diameter.

Custom Design and Engineering

Precision rings, incorporated designs, engineers, and manufactures custom industrial piston rings and seal rings. Piston rings and seals can be manufactured from an existing print or many years of engineering experience can be used to design a custom piston ring solution for the most challenging application.

Custom Eco-Friendly Seal Ring Manufacturing

Proper seals promote an all-around healthier environment. Whether it’s preventing harmful substances such as jet fuel and “heavy” water from nuclear power plants from entering the atmosphere, eco-friendly seal rings provide the needed leakage protection.

Custom Piston Ring and Seal Industries Served

Precision rings, incorporated is a custom piston ring and seal manufacturer for all types of industrial applications. Precision rings, incorporated custom designs, engineers, and manufactures piston rings and seals for the following industries:

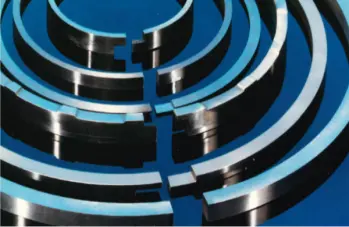

Manufacturing Large Diameter Rings

Need large diameter rings manufactured to specifications? Precision rings, incorporated manufactures rings with different end style configurations and ring types based on the application requirements. Whether it’s rings as small as 0.200” (5.08 mm) in diameter or large diameter rings over 100” (2,540 mm), Precision rings, incorporated gets it done!

Heat Treatment

Precision rings, incorporated’s custom heat-treating process is Nadcap approved and provides the following temperature standards:

- Furnaces: 2250°F (1232°C)

- Deep Freeze: -100°F (-73°C)

Turning

Precision rings, incorporated’s innovative turning processes are extremely accurate, providing precise results for numerous applications. Turning features include:

- CNC Lathes

- Accuracy +/- .0002

- CNC Machine Centers

- Repeat Accuracy: +/- .0002

- Vertical Turret Lathe

- Accuracy: +/- .0005

Grinding

Precision rings, incorporated’s grinding capabilities include the following capabilities:

- O.D. and I.D. Accuracy: +/- .0002

- Blanchard Accuracy: +/- .0004

Milling

Precision rings, incorporated’s custom milling processes provide exceptional results that are extremely accurate. Milling features include:

- Repeat Accuracy: +/- .0002

Coordinate Measuring Machine (CMM)

Coordinate measuring machines (CMM) accurately measure a part’s height, width, and depth. CMM machine accuracy measurements provide the following range:

- Accuracy: +/- .0002

Custom Piston Ring Material Options

Precision rings, incorporated uses various materials when manufacturing custom piston rings and seal rings. These include the "Superalloys", materials of high Nickel or Cobalt content that provide excellent properties for harsher environments, while polymers provide good sealing characteristics for lower temperature applications.

The application often determines the material form. The ring material must be compatible with the mating materials in a system. The correct material allows the ring to be the sacrificial part in a properly engineered system.

The following list is the most common materials used by Precision rings, incorporated for custom piston rings and seal rings in high heat, cryogenic temperature, corrosive fluid, and high-pressure applications. Please note that this is not an exhaustive list of materials or capabilities.

- 300 and 400 Series Stainless

- 17-7 PH®

- 17-4 PH®

- Stellite® 25

- Stellite® 31

- Inconel® X-750

- Inconel® 718

- Inconel® 792

- Inconel® 625

- Inconel® 600

- Waspaloy®

- Aluminum Bronze

- Aluminum Alloy

- Rene 41®

- A286

- K-Monel®

- Hastelloy®

- S-Monel

- Torlon®

- Virgin Teflon

- Vespel DuPont® SP-1, SP-21, and SP-22

- Titanium Alloy

- Ni-Resist Irons

- Nitronic® 60

Not sure which material to use? Contact Precision rings, incorporated for a material recommendation.

Surface Treatments

The following list is the most common surface treatments used by Precision rings, incorporated for custom piston rings and seal rings. Please note that this is not an exhaustive list of surface treatments used.

- Dry Films

- Silver Plating

- Chromium Plating

- Phosphate Coatings

Precision rings, incorporated Quality Assurance

Quality Assurance (QA) is a very integral part of production operation. Statistical analysis is used to monitor processes and products. All material processes are certified by Precision rings, incorporated’s Quality Assurance. Precision rings, incorporated’s QA department utilizes several inspection points that check every product with sophisticated instrumentation dimensionally. This detailed QA process permits each custom piston ring to be manufactured with minimal tolerances, providing the best leakage control possible.

Value and Sophistication

The word precision signifies quality. Precision rings, incorporated is a quality-oriented company. Precision rings, incorporated provides customers with the highest quality standards. Quality, value, and sophistication are apparent in every action Precision rings, incorporated executes. These high-value standards include responding to an inquiry, piston ring design, measuring ring flatness, studying heat treat furnace working zone uniformity, or finished product packaging.

Precision rings, incorporated Program Operations

Precision rings, incorporated is committed to keeping pace with industry changes. Equipment updating with continuous research and development guarantees uniform product manufacturing.

- Continuous improvement

- Supplier audit/rating

- Advanced quality systems

Contact Precision rings, incorporated for Custom Seal Piston Ring Manufacturing Capabilities

Learn more about Precision rings, incorporated’s custom piston and seal ring design and engineering services by contacting the sales team or calling 317-247-4786 for assistance. Precision rings, incorporated is the premier source for advanced piston ring and seal ring design and manufacturing capabilities.

Copyright and Trademark Notices

* NITRONIC®, 17-4 PH®, and 17-7 PH® are registered trademarks of Cleveland-Cliffs Steel Corp.

* HAYNES® and HASTELLOY® are registered trademarks of Haynes International.

* INCONEL® and MONEL® are registered trademarks of Special Metals Corporation.

* TORLON® is a registered trademark of Solvay Specialty Polymers USA, L.L.C.

* RENE 41® is a registered trademark of Teledyne Industries, Inc.

* WASPALOY® is a registered trademark of the United Technologies Corp.

* STELLITE® is a registered trademark of Kennametal, Inc.

* VESPEL® is a registered trademark of Dupont Polymers, Inc.