Not Finding What You're Looking For?

Contact UsCustom Piston Ring End Styles

Selection of the proper end style configuration is essential in sealing applications. Acceptable leakage rates, sizes of the rings, and types of assembly are factors that help determine the appropriate end style configuration of piston rings and seal rings. Shown below are the most common end style configurations.

Please contact Precision rings, incorporated to inquire about an end style configuration not shown below or call 317-247-4786 to consult with the engineering department for proper end style selection. The engineers can help select an end style configuration suited to the application requirements.

Why Choose Precision rings, incorporated for Custom Precision Ring Needs?

Precision rings, incorporated designs and manufactures custom end style configurations to meet today’s demanding operating conditions. Custom end style solutions are designed and manufactured to conform to each customer’s unique operational needs.

Precision rings, incorporated provides the industry’s most advanced technical leadership, manufacturing expertise, imagination, and creativity combined with an overwhelming desire to provide custom end style configurations that meet or exceed customer requirements.

Contact UsCustom End Style Configuration Options

Precision rings, incorporated provides custom piston ring end style solutions for your application’s unique specifications. Precision rings, incorporated’s custom piston end style configuration options include:

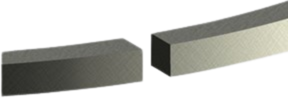

SQUARE CUT:

The most practical and economical end style options. Recommended for most applications. Good leakage control.

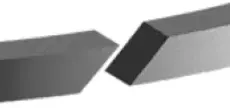

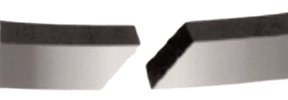

ANGLE CUT:

Widely used on rotating seals. Rings should be oriented so the leading edge points in the direction of rotation. Rings with an angled end style decrease the tendency to score at the gap.

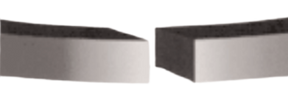

TITE JOINT:

Sometimes applied to contracting and snap rings to provide simple removal from the groove.

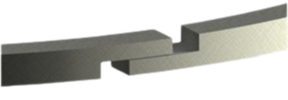

STEP CUT:

Used where two rings per groove are not practical. The step end style prevents a direct flow path between the piston and cylinder. The section must be larger to accommodate the strength of the steps.

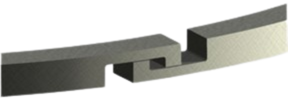

HOOK STEP:

Used for blind assembly or when the ring must pass ports in the cylinder wall. Limits free expansion.

MITRE STEP:

This single piece ring option delivers tighter leakage control by blocking all open gaps. Rings of medium to larger diameters permit the use of this end style.

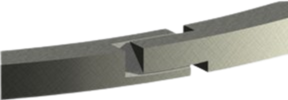

MITRE HOOK STEP:

This ring can maintain low leakage and restrain the free diameter for blind assembly. Used on medium to large rings with adequate space to accommodate the complex feature.

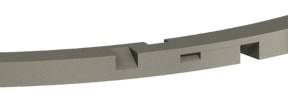

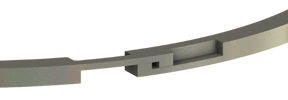

POCKET HOOK STEP:

This ring can maintain low leakage and restrain the free diameter for blind assembly. Used on medium to large rings with adequate space to accommodate the complex feature. Applicable where pressure will reverse.

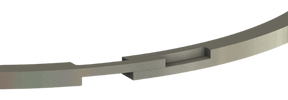

POCKET STEP:

Similar to the mitre step, this single piece ring blocks all open gaps for tighter leakage control. Used on medium to large rings with adequate space to accommodate the complex feature. Applicable where pressure will reverse.

Contact Precision rings, incorporated for Custom End Style Configurations Today

Precision rings, incorporated is a Nadcap, ISO 9001:2015, and AS9100D certified manufacturer of custom end style configurations. Precision rings, incorporated has the experience and expertise to produce custom piston rings that meet performance needs and exceed expectations. To learn more about the company’s custom piston end style configurations. Contact Pri today or Request a Quote.