Not Finding What You're Looking For?

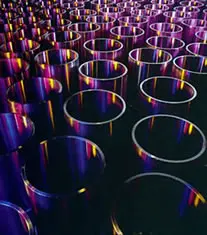

Contact UsHigh-Quality Piston Ring Materials and Advance Surface Treatments

Precision rings, incorporated is a design engineering and manufacturing solutions provider of high-quality piston rings and seal rings. Precision rings, incorporated’s custom piston rings and seal rings are designed to meet a range of industrial applications, including those for the aerospace and aircraft, power generation, green energy, military and defense, and industrial markets, providing quality products, dependable service, and on-time delivery. Contact us or request a quote or design today!

Diverse Material Options for Manufacturing Piston Rings

Precision rings, incorporated’s piston rings are manufactured from a range of materials, providing options to meet various industrial applications. Piston ring material options include:- Waspaloy®

- Vespel DuPont®

- Aluminum Bronze

- Aluminum Alloy

- A286

- Hastelloy®

- Torlon®

- Titanium®

- And more

Featured Aerospace Superalloys

Inconel® Superalloys: Exceptional Performance in Extreme Environments

Inconel is a family of nickel-chromium-based superalloys known for their excellent oxidation and corrosion resistance. Inconel® is suitable for applications that exist in extreme heat and aggressive environments, such as space and high altitudes.

Stellite® Superalloys: Unmatched Wear and Corrosive Resistance

Stellite is a cobalt-chromium alloy renowned for its exceptional wear and corrosion resistance. Stellite is ideal for applications that require high-temperature environments, such as valve seats, where resistance to wear and friction are critical.

Hastelloy® Superalloys: Superior Corrosion Resistance for Various Environments

Hastelloy refers to a group of nickel-molybdenum alloys that offer excellent resistance to various corrosive environments, including acids and seawater. It's commonly used in chemical processing, pollution control, and marine applications.

Waspaloy® Superalloys: High-Strength Solution for Aerospace Applications

Waspaloy is a high-strength, nickel-based superalloy that displays exceptional creep and fatigue resistance. It's often employed in aerospace applications, such as turbine disks and other high-stress components.

Contact Us

Advanced Surface Treatments for Enhancing Piston Ring Performance

Piston ring surface treatments are available in the following options:- Dry Films

- Silver Plating

- Chromium Plating

- Phosphate Coatings

Global Supplier of Custom Piston Rings for Aerospace, Power Generation, and More

Precision rings, incorporated designs and manufactures custom piston and seal rings for various applications. A global supplier of sealing solutions, custom rings from Precision rings, incorporated are used in several industries, including:Precision rings, incorporated’s Certifications and Quality Assurances

Precision rings, incorporated is committed to delivering quality custom piston and seal rings to industries throughout North America. Precision rings, incorporated’s certifications and Quality assurances include:Contact Precision rings, incorporated for Custom Piston Ring Material Options and Surface Treatments Today

Not sure which material to use? Contact Precision rings, incorporated or call 317-247-4786 to consult with the engineering department for more information on the piston ring material options or surface treatments.

Copyright and Trademark Notices

* 17-4 PH® and 17-7 PH® are registered trademarks of Cleveland-Cliffs Steel Corp.

* INCONEL® is a registered trademark of Special Metals Corporation.

* STELLITE® is a registered trademark of Kennametal, Inc.

* WASPALOY® is a registered trademark of the United Technologies Corp.

* VESPEL® is a registered trademark of Dupont Polymers, Inc.

* HASTELLOY® is a registered trademark of Haynes International.

* TORLON® is a registered trademark of Solvay Specialty Polymers.