Not Finding What You're Looking For?

Contact UsSealing Mechanics Solutions for Effective Sealing

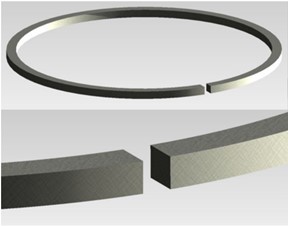

Many factors are considered when designing custom piston rings and seal rings to create the best, most effective sealing solution. These factors include but are not limited to operating stresses, assembly stresses, thermal expansion, and leakage requirements.

Precision rings, incorporated (Pri) understands proper sealing mechanics' benefits, including primary and secondary sealing. Precision rings, incorporated’s experts have the knowledge and experience to manufacture custom piston rings based on project specifications.

Contact the sales team to learn more about Precision rings, incorporated’s sealing mechanics and primary and secondary sealing solutions, or call 317-247-4786 for assistance. Precision rings, incorporated is the premier source for advanced piston and seal ring design and manufacturing capabilities. Contact Us

Primary Sealing

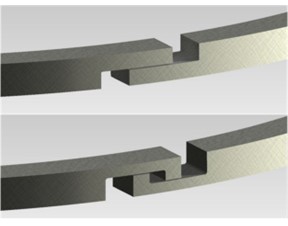

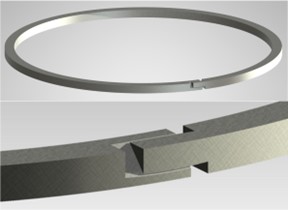

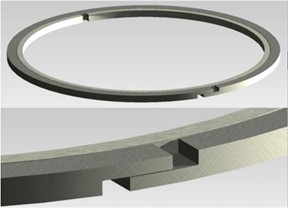

In the case of an expanding ring, primary sealing is established between the outside diameter (OD) of the ring’s surface and the cylinder bore. The primary sealing is formed for contracting rings where the ring’s inside diameter (ID) makes contact with the piston/shaft/rod. Contact is maintained by the inherent tension built into the ring until the pressure differential is sustained across the ring. This pressure differential keeps the ring "seated," forming an effective seal.

Secondary Sealing

Secondary sealing is created by contact between the ring’s side face and the groove wall. The desired clearance between the ring and its groove forms a flow channel that carries fluid to the back of the ring, establishing a pressure differential. Once an ideal pressure differential is attained, the unbalanced reacting forces at the sides of the ring allow it to seat and form an effective seal. Both primary and secondary sealing produce the desired sealing action for the application.

Drag Forces

The same factors that contribute to seating a piston ring also create drag forces. Axial drag forces result from high-pressure fluid acting on the ring's I.D. (expanding ring) or O.D. (contracting ring) surface and the coefficient of friction between mating surfaces. In addition to this force, drag forces must be considered due to the ring’s inherent tension. In very high-pressure applications, these drag forces become almost negligible by comparison. Rings must be carefully designed for low-pressure applications to compensate for drag forces.

Another type of drag force is caused by friction between the side face of the ring and the groove's side surface. The ring will not achieve primary sealing contact if this side drag force is too large. Again, this drag force must be carefully balanced while designing the ring for low-pressure applications.

Contact Precision rings, incorporated for Effective Sealing Mechanics Execution Today

Sealing mechanics, including primary and secondary sealing solutions, account for operating stresses, assembly stresses, thermal expansion, and leakage requirements. Learn more about Precision rings, incorporated's custom piston ring sealing solutions by contacting the sales team or calling 317-247-4786 for assistance.